Unit - Chemistry of Garments: Synthetic (man-made) Fibres

Acrylic,

Aramid (

Twaron,

Kevlar,

Technora,

Nomex),

Microfiber,

Modacrylic,

Nylon,

Olefin

Polyester,

Polyethylene (

Dyneema,

Spectra),

Spandex,

Vinylon,

Vinyon,

Zylon

Nylon (Polyamide)

Nylon is a thermoplastic silky material, first commercially used

in a nylon-bristled

toothbrush (1938). Following a US nationwide campaign DuPont sold

around 5 million pairs of "nylons" (stockings) on the 15th May 1940.

The name may have been derived from 'no-run' to emphasise the durability of the

stockings produced from it.

|

|

|

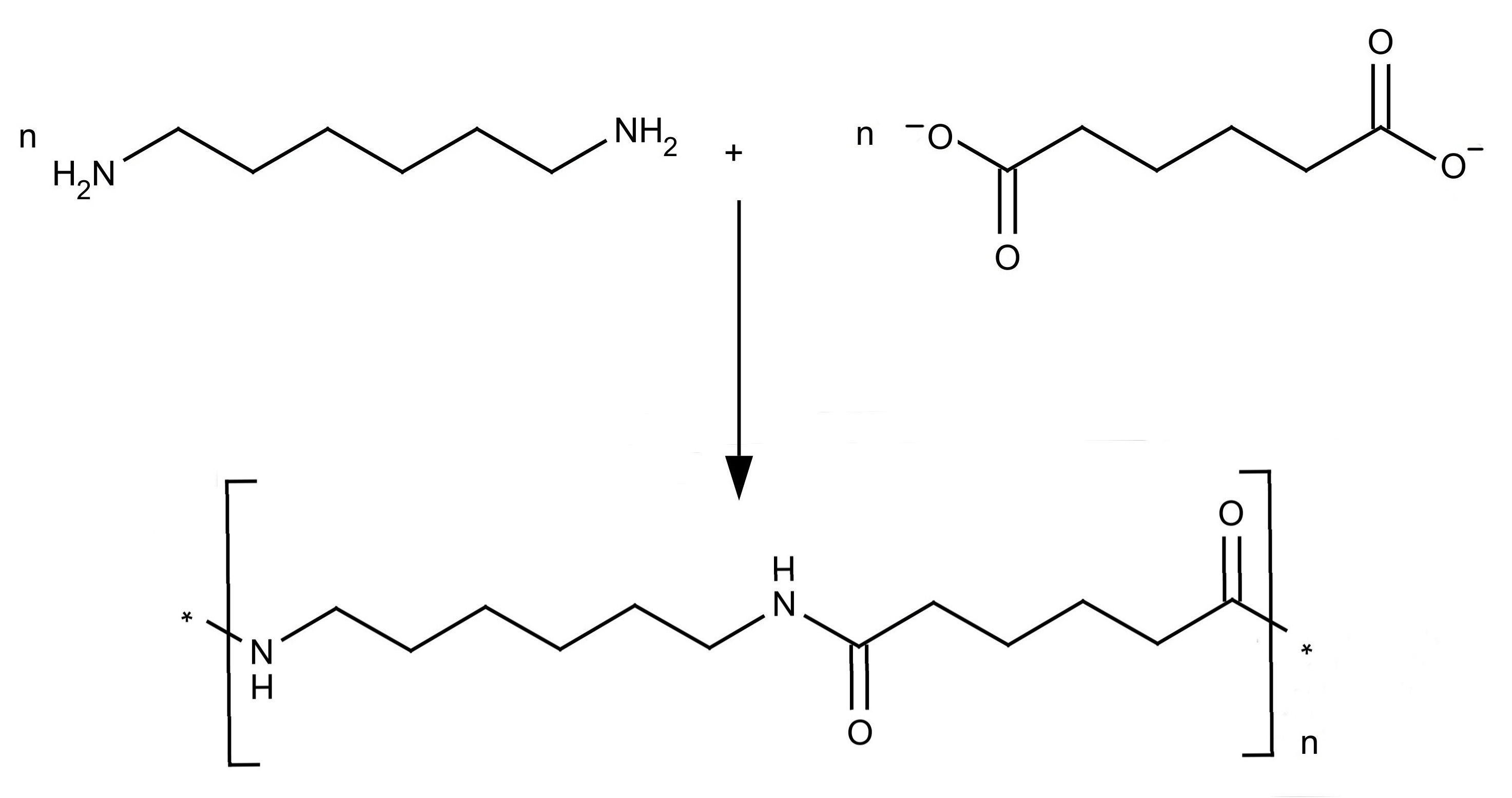

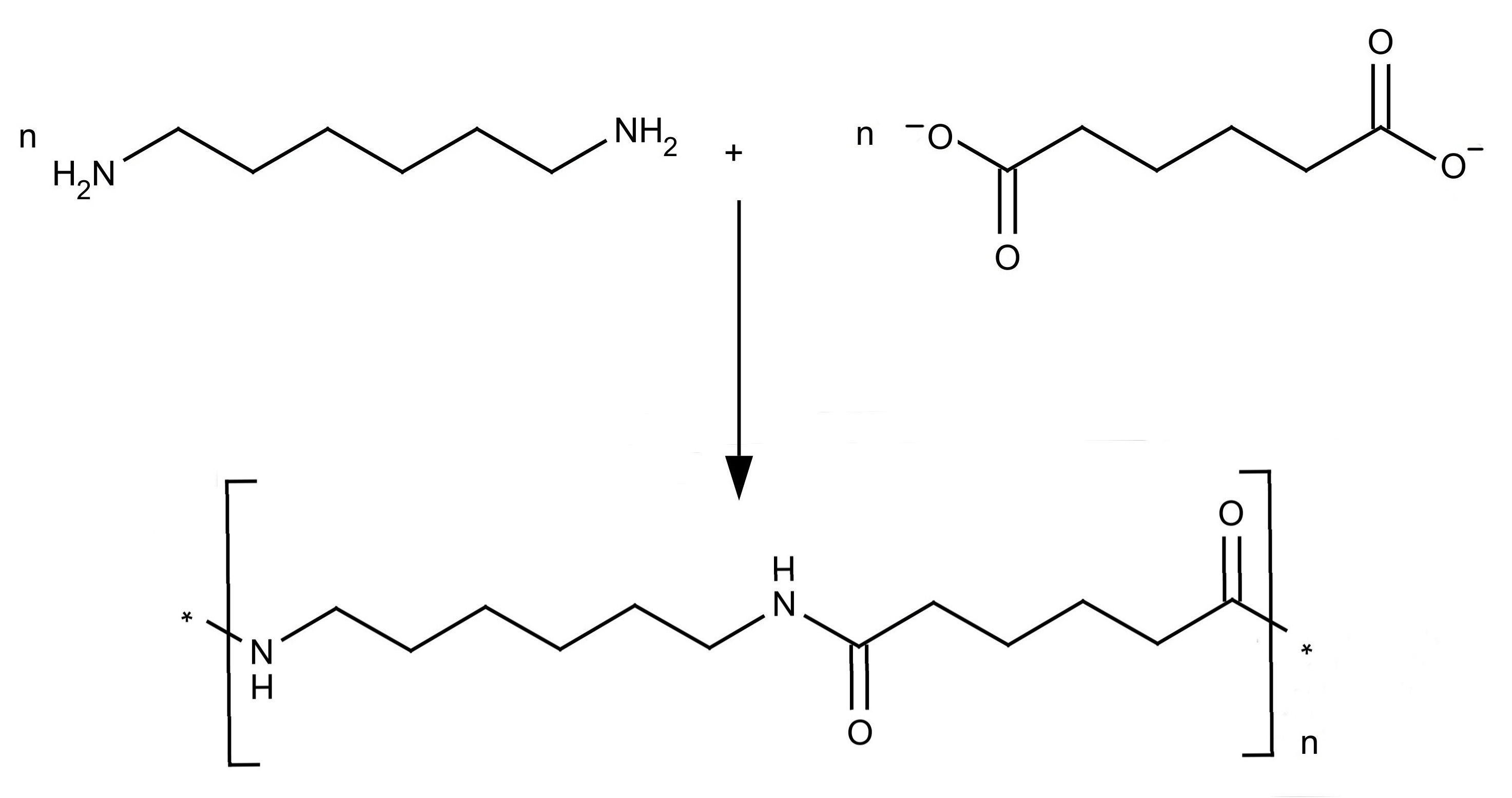

Preparation and structure of Nylon 6 6

|

Nylon was the first synthetic fibre to be made. Nylon-66 and

Nylon-6 are the two important synthetic fibres belonging to the

polyamide group. The numerical suffixes specify the number of

carbons donated by the monomers; the diamine first and the diacid

second. The most common variant is Nylon 6-6 which refers to the

fact that the diamine (hexamethylene diamine, IUPAC name:

hexane-1,6-diamine) and the diacid (adipic acid, IUPAC name:

hexanedioic acid) each donate 6 carbons to the polymer chain. The

Nylon salt so formed on polymerization gives polyhexamethylene

adipamide.

Crystallinity

Note that the molecular graphic images on these pages suggest a

high degree of regular crystallinity which is generally not the

case.

When applied to polymers, the term crystalline has a somewhat

ambiguous usage. In some cases, the term crystalline finds

identical usage to that used in conventional crystallography. For

example, the structure of a crystalline protein or

polynucleotide, such as a sample prepared for x-ray

crystallography, may be defined in terms of a conventional unit

cell composed of one or more polymer molecules with cell

dimensions of hundreds of angstroms or more.

A synthetic polymer may be loosely described as crystalline if it

contains regions of three-dimensional ordering on atomic (rather

than macromolecular) length scales, usually arising from

intramolecular folding and/or stacking of adjacent chains.

Synthetic polymers may consist of both crystalline and amorphous

regions; the degree of crystallinity may be expressed in terms of

a weight fraction or volume fraction of crystalline material. Few

synthetic polymers are entirely crystalline.

The crystallinity of polymers is characterized by their degree of

crystallinity, ranging from zero for a completely non-crystalline

polymer to one for a theoretical completely crystalline polymer.

Polymers with microcrystalline regions are generally tougher (can

be bent more without breaking) and more impact-resistant than

totally amorphous polymers.

Polymers with a degree of crystallinity approaching zero or one

will tend to be transparent, while polymers with intermediate

degrees of crystallinity will tend to be opaque due to light

scattering by crystalline or glassy regions. Thus for many

polymers, reduced crystallinity may also be associated with

increased transparency.

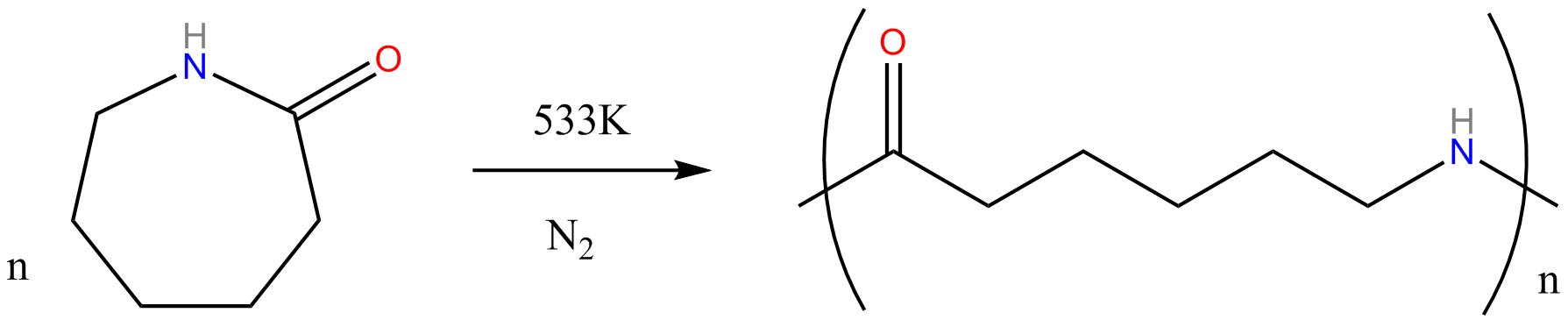

Nylon 6 or

polycaprolactam is a polymer developed at IG Farben to

reproduce the properties of nylon 6,6 without violating the

patent on its production. Unlike most other nylons, nylon 6 is

not a condensation polymer, but instead is formed by ring-opening

polymerization of caprolactam (with 6 C's in the ring, hence the

name).

Although Nylon thread looks delicate, it is in fact as strong as

steel. It has only one-seventh the weight of a steel wire of the

same diameter and hence its tensile strength per unit weight is

superior to that of steel. Because of its great strength, it is

used in making hosiery, textiles, ropes, upholstery, tooth brush

bristles, paint brushes, fishing lines and nets, tennis racquets,

sewing thread, syringes, spectacle frames, zip fasteners and

vehicle tyres blended with rubber. Synthetic grass, which has

been used on tennis courts is made from Nylon. Nylon also

improves the utility of wool fabrics and in mouldable form, it is

used for making bearings and gears, which are self-lubricating.

Preparation of thread of Nylon 6 10 in the Physical Chemistry

Laboratory

Aramids: Kevlar and Nomex

According to the FTC an aramid is defined as:

"A manufactured fibre in which the fibre-forming substance is a long-chain

synthetic polyamide in which at least 85% of the amide (-CO-NH-)

linkages are attached directly between two aromatic rings".

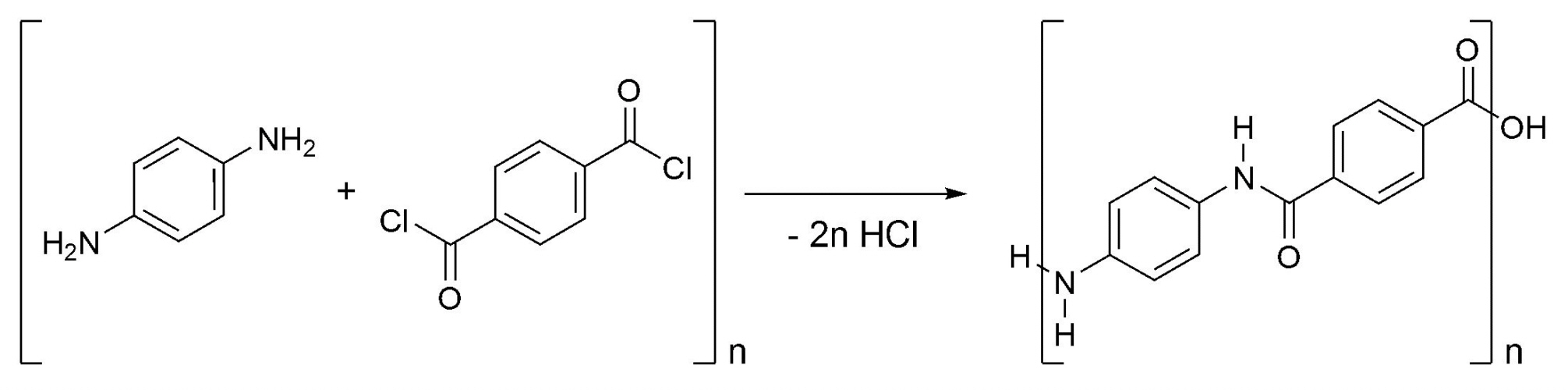

Kevlar

Poly-paraphenylene terephthalamide - better known by the

Trademark, Kevlar - was patented by DuPont in 1962. A research

group at DuPont, began searching for a new lightweight strong

fiber as a substitute to use in the manufacturing of light but

strong tyres having recognised that gasoline resources were

limited. The polymers they had been working with prior to that

time were poly-p-phenylene-terephthalate and polybenzamide, which

formed liquid crystals while in solution, something unique to

those polymers at the time.

In recalling the critical experiment, the discoverer,

Stephanie Kwolek

(1923-2104)

reported that the solution was "cloudy,

opalescent upon being stirred, and of low viscosity" and usually

was thrown away. However, Kwolek persuaded the technician who ran

the "spinneret", to test her solution, and was amazed to find

that the fibre formed did not readily break, unlike nylon. Her

supervisor and her laboratory director understood the

significance of her discovery and within a few years (1971)

modern Kevlar was introduced.

Kevlar can be synthesized in solution from the monomers 1,4-phenylene-diamine

(para-phenylenediamine) and terephthaloyl chloride in a condensation reaction.

Kevlar's structure consists of relatively rigid molecules which

tend to form mostly planar sheet-like structures similar to silk

protein. It has a high strength/lightweight combination that

makes it the perfect solution for a variety of applications:

- Kevlar K-29 - in industrial applications, such as cables,

asbestos replacement, brake linings, and body/vehicle

armour.

- Kevlar K49 - high modulus used in cable and rope

products.

- Kevlar K100 - coloured version of Kevlar

- Kevlar K119 - higher-elongation, flexible and more fatigue

resistant.

- Kevlar K129 - higher tenacity for ballistic

applications.

- Kevlar AP - has 15% higher tenacity than K-29.

- Kevlar XP - lighter weight resin and KM2 plus fibre

combination.

- Kevlar KM2 - enhanced ballistic resistance for armour

applications

Some of the characteristics that make Kevlar useful in protective

applications:

- Bullet resistant

- Fragment resistant

- Excellent thermal properties

- Lightweight

- Flexible

- Excellent dimensional stability

- Comfortable

- High strength

- Cut resistant

- Chemical resistance

- Puncture resistant

- Slash resistant

- Flame resistant, self-extinguishing

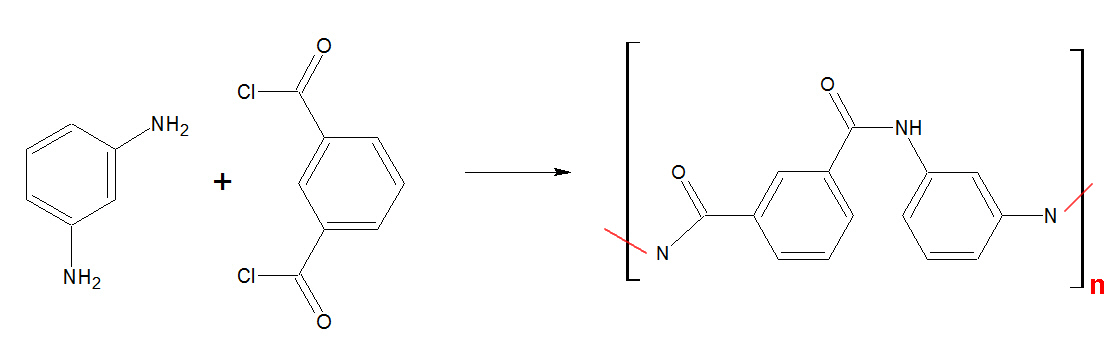

Nomex

Nomex,

which handles similarly to normal textile apparel fibers, is

characterized by its

excellent resistance to heat, as it neither melts nor

ignites in normal levels of oxygen. It is extensively used in the production

of protective apparel, air filtration, thermal and electrical insulation

as well as a substitute for asbestos.

The polymer can be produced by a condensation reaction from the monomers

1,3-phenylene-diamine (m-phenylenediamine) and isophthaloyl chloride.

Polyesters

Polyester is made under a range of brand names including: Dacron

(USA), Diolen, Fortel, Kodel, Tergal, Terlenka, Terylene (UK),

Tetoron, Trevira (Germany) and Vycron.

Synthesis of polyesters is generally achieved by a polycondensation reaction.

The general equation for the reaction of a diol with a diacid is:

(n+1) R(OH)2 + n R'(COOH)2 → HO[ROOCR'COO]nROH + 2n H2O

|

|

|

Tall ship replica Surprise, with poly(ethylene terephthalate)

(PET) sails from 125,000 recycled soft-drink bottles.

|

The polyester PET is based on the petroleum products ethylene

glycol and terephthalic acid and is called poly(ethylene

terephthalate). The fibres are linear, long stretched

filamentous molecules. Polyester-cotton blends are popular for

making fabrics, which are used in winter-suits, shirts,

pullovers, socks, carpets, parachute cloth, ropes, wire

insulators, and blankets. Polyesters contribute several

properties to blends, such as wash- and-wear quality,

wrinkle-free texture. Rayon is made from cellulose, cuprammonium

and viscose, it is very cheap and can easily be blended with

other materials as well. Terylene is blended with cotton to

produce what is known as terycot, which is crease resistant and

comfortable as cotton.

The majority of the world's PET production is for synthetic

fibers (in excess of 60%), with bottle production accounting for

around 30% of global demand. In discussing textile applications,

in general PET is referred to as simply "polyester," whereas

"PET" is used most often to refer to packaging applications. The

polyester industry makes up about 18% of world polymer production

and is the third-most-produced polymer; polyethylene (PE) and

polypropylene (PP) are first and second, respectively.

PET

Recycling

Resin identification code used on bottles to allow for recycling of

PET

PET has a

resin identification code of 1. While most

thermoplastics can, in principle, be recycled, PET bottle

recycling is more practical than many other plastic applications.

The primary reason is that plastic carbonated soft drink bottles

and water bottles are almost exclusively PET. It seems as though

only those with resin identification codes 1 and 2 are actually recycled.

The first drink bottles manufactured with PET had round bottoms

and a second plastic (black polyethylene) as a cup on the bottom

to provide a base. This was because the sharp bend needed to make

a flat base weakened the plastic. Current designs mould a bottom

with five, or more convolutions all of which have rounded edges

and this eliminates the need for a second plastic and means that

during the recycling process there is no need to separate the

plastics.

According to the PCI

Group, in 2009 approximately 5.8 million tons of recycled PET

were collected worldwide. From this 4.7 million tons of flake

were obtained. 3.4 million tons were used to produce fibre, 0.5

million tons to produce bottles, 0.5 million tons to produce APET

sheet for thermoforming, 0.2 million tons to produce strapping

tape and 0.1 million tons for miscellaneous applications.

Recycling video

- from water bottles to clothing.

The world's largest

"bottle-to-bottle" plastic recycling plant in Riverside, California, USA.

Acrylic Fibres

(polyacrylonitrile, PAN)

Polyacrylonitrile is known by a number of brand names, including:

Acrilan, Creslan, Orlon and Zefran (all of which have 10% to 14%

of other monomers added to improve dyeing), Verel (which is 40%

to 50% vinyl chloride), Dynel (more than 50% vinyl chloride) as

well as Belson, Casmilon, Courtelle, Crylor, Darvan, Teklan and

Vonnel. PAN thus represents a whole family of fibres, which can

be prepared by the polymerization of acrylonitrile.

About 90% of the world's acrylonitrile is manufactured today by the

ammoxidation of propene i.e. mixing propylene, ammonia and oxygen.

The liquid acrylonitrile upon polymerization is converted to polyacrylyonitrile, a

synthetic resin powder. As a textile material polyacrylonitrile

is lighter than wool, soft and warm. It can be washed and

drip-dried. It is used as a cheaper substitute of wool for making

warm clothes. Orlon is used in making coats, pullovers, carpets,

and blankets.

Process steps involved in the production of acrylonitrile are:

- Catalyst preparation: for example Bi2O3.MoO3

containing bismuth and molybdenum

- Mixing of propylene, ammonia and oxygen in 1:1:6 ratio

- Reaction section: acrylonitrile, acetonitrile, hydrogen cyanide,

unreacted mixtures of propylene, ammonia and oxygen are fed to a fluidised bed reactor

- Reaction is highly exothermic.

- Removal of ammonia

- Absorption of absorbable component from ammonia free gas in water to

separate the non-condensable and unconverted propylene, propane, nitrogen, CO and CO2

- Stripping of organic components and separation of HCN

- Separation of Acrylonitrile and acetonitrile which are close boiling compounds.

These are separated by extractive distillation using water as solvent.

A dilute solution of acrylonitrile is separated which is recovered and concentrated

- Purification of acetonitrile

- Final purification of acrylonitrile

Formation of acrylonitrile occurs by the following reactions:

CH2=CH-CH3 + O2 → CH2=CH-CHO + H2O

CH2=CH-CHO + NH3 → CH2=CH-CH=NH + H2O

CH2=CH-CH=NH + 1/2 O2 → CH2=CH-CN + H2O

Overall reaction:

CH2=CH-CH3+ NH3+ 3/2 O2 → CH2=CH-CN + 3 H2O

Side reactions include:

2 CH2=CH-CH3 + 3 NH3+ 3 O2 → 3 CH3CN + 6 H2O

Russian Journal of Applied Chemistry, Volume 79, Number 8,

1378-1380, DOI:

10.1134/S1070427206080349

Polyacrylonitrile (PAN) is one of the most important and widely

industrially used polymers. It serves to obtain various polymeric

materials with unique properties (thermal stability, strength,

electrical conductivity, hydrophilicity, etc.). This is

determined by specific structural features of the PAN molecule,

whose quantitative and qualitative parameters depend on

preparation techniques and methods of its modification. Various

methods of acrylonitrile polymerization can he used to obtain

polymers with predominance of 3D structures of atactic,

isotactic, and syndiotactic types. Stereoisomers of this kind

possess various properties and differently behave in forming and

under thermal treatment. The "wet" method is for the most part

used in the industry to form PAN fibers, and, therefore, the

spatial orientation of polymer chains of PAN in solution is

important. As a rule, spinning solutions of PAN arc oriented by

mechanical treatment in fibre forming on a technological line.

Tacticity is

a term used to describe the structures of polymers.

Isotactic polymers are composed of

isotactic macromolecules (IUPAC definition). In

isotactic macromolecules all the substituents are located on the

same side of the macromolecular backbone. Isotactic polymers are

usually semicrystalline and often form a helix configuration.

In syndiotactic or syntactic macromolecules the

substituents have alternate positions along the chain. The

macromolecule consists 100% of racemo diads.

In atactic macromolecules the substituents are

placed randomly along the chain. Due to their random nature

atactic polymers are usually amorphous.

In eutactic macromolecules, substituents may

occupy any specific (but potentially complex) sequence of

positions along the chain. Isotactic and syndiotactic polymers

are therefore instances of the more general class of eutactic

polymers.

|

|

|

A syndiotactic fragment of polyacrylonitrile (PAN)

|

Heat treatment of PAN leads initially to the formation of fused

pyridine rings and eventually to carbon

fibre. This has been used to reinforce substances, such as

epoxy resins, where lightness but great strength is required for

example in the turbine blades of jet engines.

Polyolefins

Polyethylene and polypropylene are the lightest fibres and are

generally used in blankets, upholstery, carpets and apparel. They

are difficult to dye given that there are no functional groups to

react with. Polypropylene is also a substitute for sisal in rope

making and in synthetic grass. (Question: What is the material

used at the Mona Hockey Field or the Mona track?).

Ultra-high-molecular-weight polyethylene (UHMWPE, UHMW) is a subset

of the thermoplastic polyethylene. Also known as high-modulus polyethylene,

(HMPE), or high-performance polyethylene (HPPE), it has extremely long chains,

with a molecular mass usually between 2 and 6 million u. The longer chain

serves to transfer load more effectively to the polymer backbone by

strengthening intermolecular interactions. This results in a very tough

material, with the highest impact strength of any thermoplastic presently made.

UHMWPE is synthesized from monomer of ethylene, which are bonded together to

form the base polyethylene product. These ultra-high-molecular-weight

polyethylene molecules are several orders of magnitude longer than those

of familiar high-density polyethylene (HDPE) due to a synthesis process based

on metallocene catalysts, resulting in UHMWPE molecules typically having

100,000 to 250,000 monomer units per molecule each compared to HDPE's 700

to 1,800 monomers.

When formed to fibers, the polymer chains can attain a parallel orientation

greater than 95% and a level of crystallinity from 39% to 75%. In contrast,

Kevlar derives its strength from strong bonding between relatively short molecules.

Dyneema and Spectra are lightweight high-strength oriented-strand gel spun through

a spinneret. They have yield strengths as high as 2.4 GPa (350,000 psi) and

specific gravity as low as 0.97 (for Dyneema SK75). High-strength steels

have comparable yield strengths, and low-carbon steels have yield strengths

much lower (around 0.5 GPa). Since steel has a specific gravity of roughly 7.8,

this gives strength-to-weight ratios for these materials in a range from 8 to 15

times higher than steel. Strength-to-weight ratios for Dyneema are about 40%

higher than for aramids.

UHMWPE fibers are used in armor, in particular, personal armor and on occasion

as vehicle armor, cut-resistant gloves, bow strings, climbing equipment,

fishing line, spear lines for spearguns, high-performance sails,

suspension lines on sport parachutes and paragliders, rigging in yachting,

kites, and kites lines for kites sports. Spectra is also used as a high-end

wakeboard line.

UHMWPE has over 40 years of clinical history as a successful biomaterial for

use in hip, knee, and (since the 1980s), for spine implants. An online repository,

known as the UHMWPE Lexicon, that provides

information and review articles related to medical grade UHMWPE, has been

running since 2000.

Polyurethane

See as well the GB Kauffman

J. Chem. Educ. article on polyurethanes

Methylene

diphenyl diisocyanate (MDI), is an aromatic diisocyanate that

exists as three isomers, 2,2'-MDI, 2,4'-MDI, and 4,4'-MDI with

the 4,4' isomer (InChI:UPMLOUAZCHDJJD-UHFFFAOYSA-N), being the

most widely used. MDI reacts with polyols in the manufacture of

polyurethane. Total world production of MDI and polymeric MDI is

over 2 million tonnes per year (Mt/a) and it accounted for over

60% of the isocyanate global market in the year 2000.

MDI is the least hazardous of the commonly available isocyanates

but that does not imply that it is benign. Its very low vapour

pressure reduces its hazards during handling and this has led to

it being used as a replacement to the other major isocyanate TDI.

2,4-toluene

diisocyanate (TDI) is the second most used aromatic

diisocyanate and it is largely produced for preparing

polyurethanes. It exists in two isomers, 2,4-TDI (InChIKey:

DVKJHBMWWAPEIU-UHFFFAOYSA-N) and 2,6-TDI (InChIKey:

RUELTTOHQODFPA-UHFFFAOYSA-N). 2,4-TDI is produced in the pure

state, but is often marketed as 80/20 and 65/35 mixtures of the

2,4 and 2,6 isomers respectively. It is a highly produced

diisocyanate, accounting for 34.1% of the global isocyanate

market in 2000, second only to methylene

diphenyl diisocyanate (MDI). All major producers of TDI are

members of the International Isocyanate

Institute, whose aim is the promotion of the safe handling of

isocyanates (in particular (MDI and TDI) in the workplace,

community and environment.

A Google preview of the 2003 book

MDI and TDI: Safety, Health and the Environment: A Source Book

and Practical Guide is available from the Wiley website.

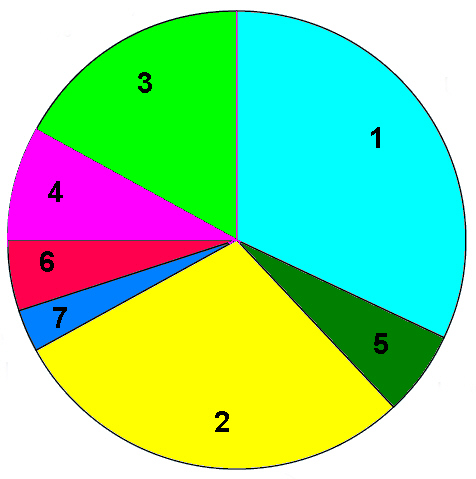

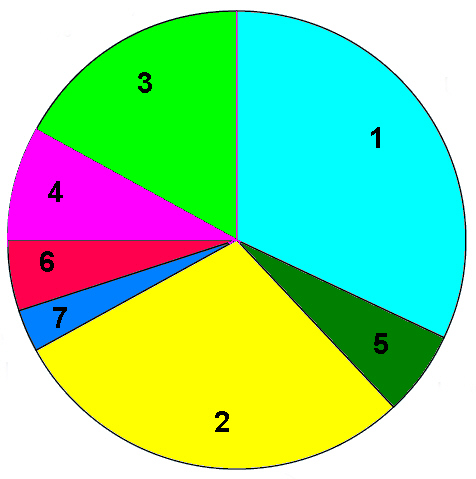

1998 Regional production figures for polyurethane

1) USA and Canada 32%, 2) Western Europe 29%, 3) Asia Pacific

excluding Japan 17% 4) Japan 7%, 5) Latin America 6%, 6) Rest of

the World 5%, 7) Eastern Europe 3%.

Spandex

Spandex is a polyurethane-polyurea copolymer that was co-invented

in 1959 by chemists C. L. Sandquist and Joseph Shivers of DuPont.

Spandex when blended with wool, cotton, nylon, linen or silk

develops properties of stretch and recovery, thus making the

blended fabrics useful for furniture upholstery, light weight

garments and

swimsuits.

Every superhero has a right to wear Spandex, schematic of the

dry-spinning process.

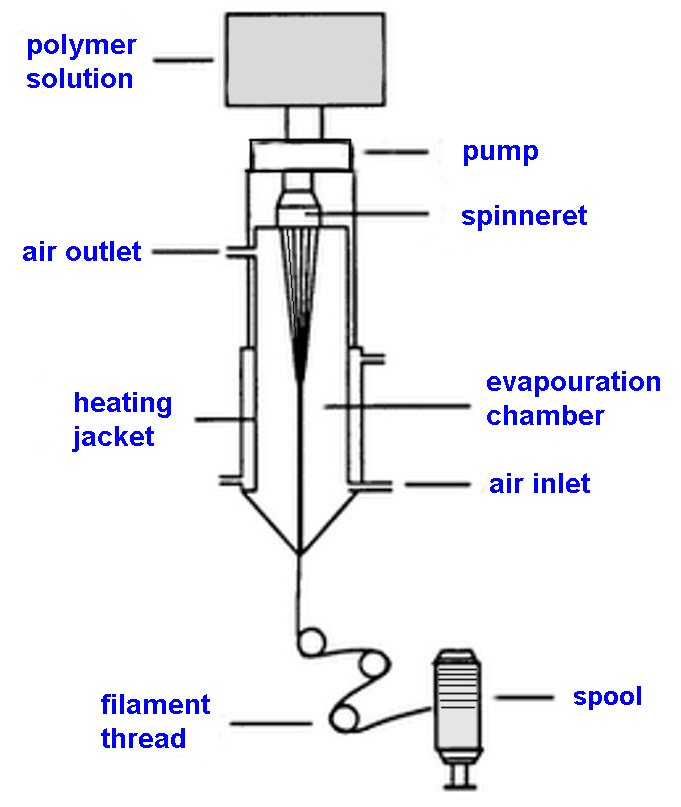

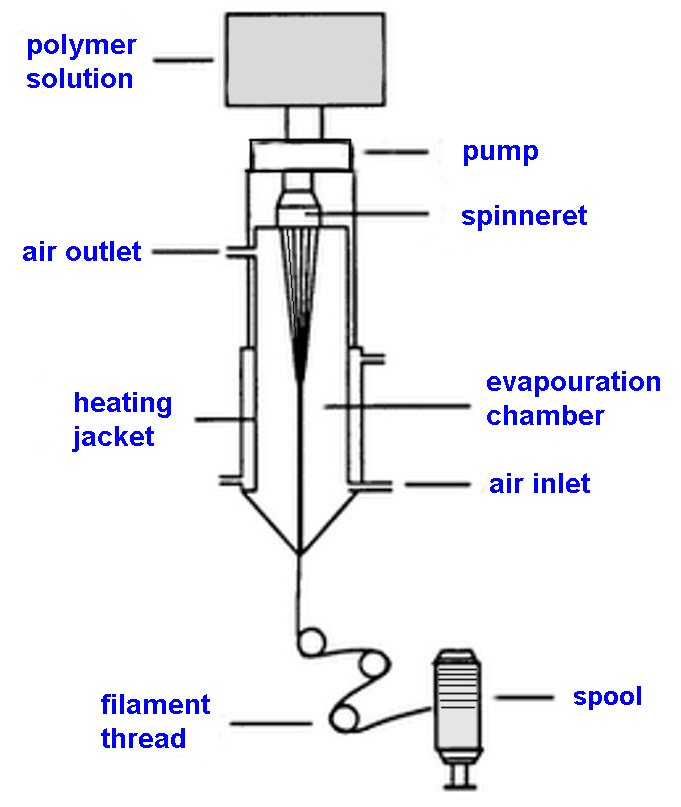

Spandex fibers are produced in four different ways: melt

extrusion, reaction spinning, solution dry spinning, and solution

wet spinning. All of these methods include the initial step of

reacting monomers to produce a prepolymer. Once the prepolymer is

formed, it is reacted further in various ways and drawn out to

make the fibers. The solution dry spinning method accounts for

over 94.5% of the world's spandex fibers.

Solution dry spinning

Step 1: The first step is to mix a macro glycol with a

diisocyanate monomer in the reaction vessel to produce the

prepolymer. A typical ratio of glycol to diisocyanate is 1:2.

Step 2: The prepolymer is further reacted with an equal amount

of diamine in what is known as a chain extension

reaction. The resulting solution is diluted with a solvent

to produce the spinning solution. The solvent helps make the

solution thinner and more easily handled so it can be pumped into

the fibre production cell.

Step 3: The spinning solution is pumped into a cylindrical

spinning cell where it is cured and converted into fibres. In

this cell, the polymer solution is forced through a metal plate

called a spinneret. This causes the solution to be aligned in

strands of liquid polymer. As the strands pass through the cell,

they are heated in the presence of nitrogen and a solvent gas.

This process causes the liquid polymer to react chemically and

form solid strands.

Step 4: As the fibres exit the cell, an amount of solid

strands are bundled together to produce the desired thickness.

Each fibre of spandex is made up of many smaller individual

fibres that adhere to one another due to the natural stickiness

of their surface.

Step 5: The resulting fibres are then treated with a finishing

agent which can be magnesium stearate or another polymer. This

treatment prevents the fibres' sticking together and aids in

textile manufacture. The fibres are then transferred through a

series of rollers onto a spool.

Step 6: When the spools are filled with fibre, they are put

into the final packaging and shipped to the textile

manufacturers.

Polylactate fibres

It has been reported that a

team of South Korean scientists have produced polymers

useful for everyday plastics through bioengineering, rather than

through the use of fossil fuel-based chemicals. This technique

may allow for the production of environmentally-friendly plastics

that are biodegradable and low in toxicity.

For a review on polylactate

fibres see the article by Jim Lunt and Associates as well as

other

articles on polymers

Non-woven Fabrics

Most non-woven fabrics are made like paper by sticking layers of

fibres together with a liquid adhesive. These fabrics are

commonly used in making hats, bra and shoulder padding,

inner-lining of suits, disposable nappy liners, duvet filling,

furniture upholstery, vacuum cleaner bags and car carpets.

Some

pros and cons of common fibres, natural and synthetic

Assignment

The examples provided above are largely based on the same

monomeric reagent polymerising to give homopolymers. Polymers

that are formed containing a mixture of repeat units are known as

copolymers.

- Choose any copolymer

- Describe the applications that it is suitable for

- Describe its structure, for example alternating, random or

block coplymer

- Identify where it is produced and by which company

- Obtain an estimate of the production figures worldwide

- What environmental issues surround its use and disposal?

Acknowledgements.

Much of the information in these course notes has been sourced

from Wikipedia under the Creative Commons License. Students

taking this course will be expected to contribute to Wikipedia as

a part of their course assignments.

Continue to Dyeing Fibres or

return to CHEM2402 course

outline.

This work is licensed under a Creative Commons

Attribution-ShareAlike 3.0 Unported License.

Return to Chemistry,

UWI-Mona, Home Page

Created and maintained by Prof. Robert J.

Lancashire,

Return to Chemistry,

UWI-Mona, Home Page

Created and maintained by Prof. Robert J.

Lancashire,

The Department of Chemistry, University of the West Indies,

Mona Campus, Kingston 7, Jamaica

Created August 2011. Links checked and/or last

modified 24th October 2016.

URL

http://wwwchem.uwimona.edu.jm/courses/CHEM2402/Textiles/Synthetic_Fibres.html

Return to Chemistry,

UWI-Mona, Home Page

Created and maintained by Prof. Robert J.

Lancashire,

Return to Chemistry,

UWI-Mona, Home Page

Created and maintained by Prof. Robert J.

Lancashire,