A Bayer plant in Jamaica

Soon after this, in 1888, Karl Joseph Bayer described what is now known as the Bayer Process, which led to a dramatic reduction in the cost of aluminum metal. Today, it is an everyday commodity, rather than a precious metal.

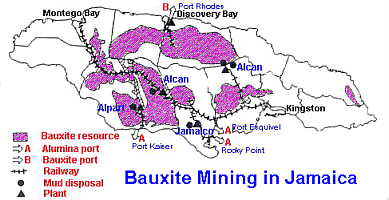

Although deposits of aluminous red earth have been known to occur in the Tertiary Limestone areas (which covers two thirds of the land surface of Jamaica) since the 1820's, it was not until the 1940's that their economic significance as an ore of aluminum was recognised.

In October, 1943, Alcan was incorporated under the name

Jamaica Bauxites Limited as a Jamaican company to investigate the

commercial potential of Jamaican bauxite. In the same year, 2500

tonnes of ore was shipped to the USA for process investigation

and it was realised that the bauxite was suitable for processing

using Bayer technology.

The Kirkvine works were completed around 1952 and the first

shipment of alumina was consigned to a Norwegian smelter in

January 1953.

The Bayer Process, which continues to be the most economical method of manufacturing alumina can be schematically summarised in a flow chart,

The surface occurrence of the ore (usually less than 100 feet) makes the deposits suitable for mining by simple opencast methods. Due to the soft, earthy nature of the ore, no drilling or blasting is generally required.

Deposits are located in areas varying from gentle undulating to rugged, hilly terrain involving major capital expenditures in establishing a system of ore transportation.

| Gibbsite (hydrargillite) | α-Al2O3.3H2O |

| Boehmite | α-Al2O3.H2O |

| Diaspore | β-Al2O3.H2O |

| Hematite | α-Fe2O3 |

| Goethite | α-FeOOH |

| Magnetite | Fe3O4 |

| Siderite | FeCO3 |

| Ilmenite | FeTiO3 |

| Anatase | TiO2 |

| Rutile | TiO2 |

| Brookite | TiO2 |

| Halloysite | Al2O3. 2SiO2.3H2O |

| Kaolinite | Al2O3. 2SiO2.2H2O |

| Quartz | SiO2 |

|

a = 8.684 b = 5.078 c = 9.736 α = 90 β = 94.54 γ = 90 volume = 427.985 space group = P 1 21/n 1 |

|

| Gibbsite | |

In order to remove the iron oxides and most of the silicon oxides present, the ore is first treated with sodium hydroxide. The digestion process takes advantage of the solubility of amphoteric aluminum oxides to form a solution of aluminate ions, whilst the basic iron oxides which form do not dissolve and are separated by filtration.

Gibbsite Al2O3.3H2O + 2NaOH → 2 NaAlO2 + 4 H2O (135-150 °C)

Boehmiite Al2O3.H2O + 2NaOH → 2 NaAlO2 + 2 H2O (205-245 °C)

Diaspore Al2O3.H2O + 2NaOH → 2 NaAlO2 + 2 H2O (high T and P)

Complete extraction from diasporic bauxite requires stronger

caustic solutions, in addition to higher temperatures and

pressures. In general the reaction equilibria above move to the

right with increases in caustic soda concentration and

temperature. In practice this means that for deposits containing

the more easily recovered Gibbsite only, production costs are

much lower than when Boehmite or Diaspore are present.

The control of silica in the conventional Bayer Process is most important and in fact ores having reactive silica greater than 7% cannot be economically processed.

Unlike quartz, which is considered virtually non-reactive at Gibbsite extraction temperatures, some minerals, including kaolins, dissolve rapidly and the reaction of the silica can give rise to appreciable loss of caustic soda and aluminum.

The control of silica is generally carried out during, or

prior to, the digestion step, and generally involves dissolution,

eg for kaolin

Al2O3.2SiO2 + NaOH → Na2SiO3

and desilication via precipitation.

Na2SiO3 + NaAlO2 → Na2O.Al2O3.2SiO2

Dissolution is necessary to supersaturate the liquid to a point

where the sodalite formed acts as a seed to precipitate more

sodalite. The rate of precipitation is found to increase with

temperature, however at 135-150 C it is significantly slower than

is required for complete Gibbsite extraction which occurs within

minutes. The need for desilication therefore means that the

material must be held at the digestion temperature long enough to

allow the silica to precipitate.

Still to come

For the latest statistics on bauxite/alumina production check the US Geological Surveys site

A description of the Hall process for electrolytic reduction of alumina to aluminum is appropriately provided at Oberlin College, from where Charles Hall had graduated only eight months prior to his successful experiment.

Copyright © 1995-2014 by Robert John Lancashire, all rights reserved.

Created and maintained by Prof. Robert J. Lancashire,