Chemistry and sport

Soccer -

Association Football

Association football, commonly known as football or soccer, is a

sport played between two teams of eleven players with a spherical

ball. At the turn of the 21st century, the game was played by

over 250 million players in over 200 countries, making it the

world's most popular sport. Medieval football in the UK (where villages

would play each other with an unlimited number of players on a team)

appears to date back to the eighth century at least!

In association football, the

football or soccer ball, (according to whether the game is

referred to as "football" or "soccer") used in official matches

is a specific type of football standardised for size, weight, and

material and manufactured to the specifications of the Laws of

the Game, specifically Law 2.

Law 2 of the game specifies that the ball is an air-filled sphere

with a circumference of 68-71 cm (27-28 in), a weight 410-450 g

(14-16 oz), inflated to a pressure of 0.6 to 1.1 atmospheres

(59-108 kPa, 8.6-15.7 psi) "at sea level", and covered in leather

or "other suitable material". The weight specified for a ball is

the dry weight, as older balls often became significantly heavier

in the course of a match played in wet weather. The standard ball

is a Size 5 and this is used in official FIFA championships all

over the world. The football can be made from polyurethane which

gives a less soft material but still retains a good feel and is

much more durable.

The Science of Football

Early footballs began as animal bladders that could easily fall

apart if kicked too much. As time went on footballs developed to

what they look like today. This change in the design of footballs

was helped by the introduction of

rubber and the discovery

of

vulcanization. Today, technological research continues to aid the

change in footballs with improved performance.

The

oldest football still in existence, which is thought to have

been made circa 1540, was discovered in the roof of Stirling

Castle, Scotland, in 1981. The ball is made of leather (possibly

from a deer) and a pig's bladder. It has a diameter of between

14-16 cm (5.5-6.3 in), weighs 125 g (4.4 oz) and is currently on

display at the Smith Art Gallery and Museum in Stirling.

In 1863, the first specification for footballs were laid down by

the Football Association. Prior to this, footballs were made out

of inflated leather, with later leather coverings to help

footballs maintain their shapes. In 1872 the specifications were

revised, and these rules have been left essentially unchanged as

defined by the International Football Association Board.

Differences in footballs created since this rule came into effect

have been to do with the material used in their creation.

Footballs have gone through a dramatic change over time.

During medieval times balls were normally made from an outer

shell of leather filled with cork shavings. Another method of

creating a ball was using animal bladders for the inside of the

ball making it inflatable. However, these two styles of creating

footballs made it easy for the ball to puncture and were

inadequate for kicking. It was not until the 19th century that

footballs developed into what a football looks like today.

For the 1970 FIFA World Cup, Adidas introduced the Telstar. Like

all other balls in its time, the Adidas Telstar was completely

made of leather; however, unlike any other ball it featured 32

hand-stitched panels (12 black pentagons and 20 white hexagons),

creating the now-familiar truncated icosahedron for its design

and the roundest sphere of its time.

The 1970 ball was made of leather but by 1974 the football had a

"Durlast" polyurethane coating that provided waterproofing as

well as protection from damage such as scuffs and tears.

Only 20 Telstars were provided for the 1970 World Cup however an

estimated 600,000 replicas have subsequently been sold.

Adidas Telstar Durlast 1974, Azteca Mexico 1986 and Brazuca 2014 were the

official match balls of the FIFA World Cups.

The 1986 model was the first fully synthetic FIFA World Cup ball.

The 1990 Adidas model used in Italy introduced an internal layer

of polyurethane foam and was fully made of synthetic fibers. The

underneath layer included fabric coated with latex that prevented

tearing and maintained stability. Like earlier models the outer

design was based on art forms of ancient civilizations, this time

from the Italian peninsula.

The Adidas

ball used in Korea/Japan for the 2002 World cup had a glossy

finish on the outside, an innovation that has been an inspiration

for other balls and sports products since then. Called

"Fevernova" it was made of thicker inner layers that guaranteed

the accuracy of the ball's trajectory during flight. Fevernova's

improved syntactic foam layer, consisting of highly compressible

and extremely durable gas-filled micro-balloons, had remarkable

energy return properties.

To quote some PR related to the launch of the 2010 ball:

The Adidas

JABULANI

match ball used in the 2010 FIFA World Cup in South Africa featured

completely new, ground-breaking technology. Eight three-dimensional

spherically formed ethylene vinyl acetate and thermoplastic polyurethane

panels were moulded together, harmoniously enveloping the inner carcass.

The newly developed "Grip'n'Groove" profile provides the best players

in the world with a ball allowing an exceptionally stable flight and perfect

grip under all conditions. Comprising only eight, completely new,

thermally bonded 3-D panels, which for the first time are spherically moulded,

the ball is perfectly round and even more accurate than ever before.

For the 2014 World Cup the

Brazuca was constructed in an Adidas Pakistan factory and

details of its construction were

reviewed in ChemistryViews.

Surface Panels

The surface of Brazuca is made up of only six panels of absolutely identical

shape. Conventional soccer balls consist of 12, 16, or 32 panels stiched

together. Besides leading to perfect symmetry, the reduced number of panels

of Brazuca requires fewer seams. This means that the ball is more durable

and absorbs less moisture (only 0.2 %) which makes Brazuca lighter than

other balls when played on wet ground.

The six panels are bonded together using a patented thermobonding technology.

Skin

Brazuca has five polyurethane layers:

The outer layer of the skin comprises three compact layers of polyurethane

each with different thicknesses. They are responsible for the outstanding

resistance to external influences and abrasion, and for the ball's high

elasticity.

The innermost layer of the skin is an adhesion coating that connects the

textile substrate to the layers above. On top of this is a roughly 1 mm

thick polyurethane foam layer which is made up of millions of gas-filled

microspheres. This foam is highly elastic so that the ball, after being

deformed from being kicked, immediately returns to its spherical shape to

ensure an optimal trajectory.

Bladder

The bladder in the middle of the ball holds the air. In the Brazuca,

this is made from

butyl rubber, but it can also be made from

latex.

Both have their benefits: butyl rubber retains the air for a longer

period of time, whilst latex provides better surface tension.

Butyl rubber can also be found in the valve through which air can be pumped

into the ball, where it aids air retention. Silicone valves can also be used.

Australian Football League (AFL)

Note that the AFL (founded as the Victorian Football League, VFL, in 1897)

continues to use leather footballs.

John Macadam was a

Scottish-born analytical chemist, medical practitioner and politician.

As a student he showed a flair for analytical chemistry, and

later studied medicine. He arrived in Melbourne, Australia in 1855 to take up

an appointment as lecturer in chemistry and natural science at Scotch College,

a position he held until 1865. In 1857

Ferdinand von Mueller named

the Macadamia nut after him. He officiated as one of two umpires at one of

the earliest recorded games of Australian rules football, between Scotch

College and Melbourne Grammar in 1858.

Thomas William Sherrin, born in Melbourne in 1857, repaired and manufactured

saddles and other equestrian equipment. A local VFL club would regularly

send English made leather rugby balls to Sherrin to patch and repair.

One day he decided to try and improve on the imported product

by creating an oval shaped ball with rounder points to give the ball a

better bounce. The local teams loved it and it was swiftly adopted as

their ball of choice.

Sherrin began production in 1897 in a workshop in Collingwood, which had

produced sporting goods since the 1880s. The sport known as football,

or "footy", was rapidly increasing in popularity, and Sherrin footballs

soon became the icon for being the first ball made for Australian rules

football. They remain the official ball of the AFL. Sherrin makes more than

600 balls each day (2012) and every one is still handmade.

Cricket

Cricket may have its origins in Guildford, England from as early as the 1550's.

By the end of the 18th century, it had developed into the

national sport of England. The expansion of the British Empire

led to cricket being played overseas and by the mid-19th century

the first international matches were being held. The ICC, the

game's governing body, has ten full members. The game is played

particularly in Australasia, the Indian subcontinent, the West

Indies, Southern Africa and the British Isles. It is the world's

second most popular sport.

In 2002, the WICB board received a formal request from the

management team to use Kookaburra balls for home series because

these balls were being used by all other Test-playing nations.

Prior to this, the WICB had used balls produced by Dukes, which

had a more pronounced seam. By contrast, the Kookaburra's seam is

much less "raised" and there are claims that the wear-and-tear

suffered from West Indies pitches means that after 20+ overs they

become soft and therefore less helpful to the Windies fast

bowlers.

Cross section of a cricket ball and the consistency of

manufacturing.

Despite the claims above, a study in

Australia of 5 different brands found that the Kookaburra

Special Test was the only cricket ball consistently manufactured

with respect to weight and "stiffness". The other four models

studied were found to have inconsistent stiffness, which could

play an important part in performance of the ball in play. Softer

balls like the Kookaburra brand Special Test balls were more

forgiving by causing a smaller impact force, a longer contact

with the bat, larger deflections as well as larger contact areas

during impact, and thus allowed placing the ball more precisely.

Maybe the bowlers do have a grouse then if the batsmen are able

to control the ball more consistently! I must admit to always

being amused by the expression "level playing field" when the

most hallowed cricket ground of Lords has a distinct slope to it!

What difference is there between red and white cricket

balls?

All cricket

balls (whether red, pink or white) are made from a core of

cork (or cork/rubber mixture), that is layered with tightly wound

wollen thread, and covered by a leather case with a slightly

raised sewn seam.

Cricket balls are constructed from either 2 or 4 pieces of

leather and many companies still use predominantly manual labour

in their production. Traditionally, the most expensive cricket

balls used in test matches were from 4 pieces of leather and cost

around US $ 100 while those used at other games were from 2

pieces and considerably cheaper.

When the covering is constructed from four pieces of leather, one

hemisphere is rotated by 90 degrees with respect to the other.

The "equator" of the ball is stitched with string to form the

ball's prominent seam, with a total of six rows of stitches. The

remaining two joins between the leather pieces are stitched

internally.

For men's cricket, the ball must weigh between 155.9 and 163.0 g

and measure between 224 and 229 mm in circumference.

Traditionally cricket balls are dyed red, most likely originally

by the use of the dye obtained from rose madder and it

is the red balls that are used in Test cricket and First-class

cricket. In June 2007 the ICC legalised the use of the white

ball, which some believe is actually due to it having better

visibility in TV coverage. The white balls were first introduced

when one-day matches began being played at night under

floodlights, as they are more visible under these conditions.

Professional one-day matches are now played with white balls,

even when they are not played at night.

According to

crickettamasha:

It has been claimed that the white ball is capable of swinging

more, especially during the first half of an innings, than the

red ball and that it deteriorates more rapidy, although the

manufacturers claim that their white and red balls are produced

using the same methods and materials.

In some research done by the BBC in New Zealand

with the help of the bowling machines showed that the white ball swung

appreciably more than the red ball at a pace of 70 mph. Further analysis

has made it clear about the manufacturing differences between the white

and a red ball. In a conventional red ball, the leather is dyed red, greased and

polished with a shellac topcoat. The final polish

disappears quickly during the course of the game and it is only the grease in the

leather that produces the shine when the bowler polishes the ball.

Whereas in a white ball, the leather is sprayed with a polyurethane

white paint like fluid which is then heat-treated so that it bonds to

the leather like a hard skin. An extra coating of clear polyurethane

based top coat is again applied on the white ball so that it does not get

dirty. It is this extra coat in a white ball which changes its aerodynamics

making it able to swing more.

It has been suggested that the amount of swing is dependent on the humidity

during the game. However research published in 2012 in

Procedia Engineering

and summarised at

dreamcricket

and at the

BBC

suggests that humidity during the game may not have such a large impact on

the swing of the ball.

It is possible that exposure to longer periods of low humidity may cause

cricket balls to shrink by a greater amount and become lighter, producing

outcomes that are more consistent with what has been observed in baseball

at the Coors Field, at high-altitude Denver, Colorado, USA.

Prior to 2002, large variations were observed at that ground compared to other

low-altitude grounds, but once the baseballs started to be maintained at

50% humidty in humidors, this variation was reduced.

Because a white ball becomes discoloured towards the end of a

50-over one-day innings, making it difficult for the batsman to

pick out, the International Cricket Council regulations changed

to require the use of two new balls, one from each end.

Other essentials are: gloves, shoes, protective helmets and other

protective wear, sunglasses and BLING.

A cricket joke, probably started by a woman goes:

'The first testicular guard (Box) was used in cricket in 1874 but

the first cricket helmet was used in 1974.

It took 100 years for men to realize that their brain is also

important.'

Cricket

Helmet

Graham Yallop of Australia was the first to wear a protective

helmet during a test match in March 1978 when playing against West

Indies at Bridgetown. Later Dennis Amiss of England popularized

it in Test cricket. Tony Greig was of the opinion that helmets might make

cricket more dangerous by encouraging bowlers to bounce the batsmen.

Helmets began to be widely worn thereafter. Nowadays it is almost

unheard of for a professional cricketer to face a fast bowler

without a helmet, and in under-19 cricket they are compulsory for

all batsmen and any fielder within 14 m of the bat.

Cricket helmets cover the whole of the skull, and have a grill or

perspex visor to protect the face.

Fielders who are positioned very close to the batsman (e.g. silly point

or short leg) often wear a helmet and shin guards.

The design of the cricket helmet has trailed well behind the

technologies available and in mid-2004 university tests showed

that helmets can delay a batsman's reactions by up to a quarter

of a second partly due to heat build-up and low comfort levels

caused by the weight. Inspired by those tests, designer Ravinder Sembi suggested a new

design for the cricket helmet with a view to overcoming this

fundamental problem. The helmet is designed with two

forward-facing vent holes to promote airflow when running,

conducting the air inside the helmet up and away from the head.

There is no indication however that this has yet been adopted by

cricket gear manufacturers anywhere.

An innovative cricket helmet design.

1. Titanium guard, 2. polycarbonate with film on inner side to

prevent fragments hitting face if shattered

3. ABS solid plastic injection molded with holes to allow maximum

ventilation 4. polyester strap with velcro

Ayrtek filed a patent for a new design in 2009.

This may have led to the helmet seen worn by Michael Carberry from 2013.

The helmet is designed to deflect the ball

and the rigid peak helps to reduce the risk of grille penetration.

It has a liner with an Air Cushion Impact System (ACIS) that can be

inflated or deflated to deliver a perfect fit by pushing buttons on either

side of the helmet.

R.I.P. Phil Hughes 1988-2014

Golf

Golf

Balls

An appendix to the "Rules of Golf" defines that a golf ball must

not weigh more than 45.93 grams (1.620 oz), that its diameter must not be

less than 42.67 mm (1.680 in), and that its shape may not differ

significantly from a symmetric sphere. Like golf clubs, golf

balls are subject to testing and approval by the

Royal and Ancient Golf Club of St Andrews, Scotland and the

United

States Golf Association, and those that do not conform with

the regulations may not be used in competitions (Rule 5-1).

How are golf balls made and what changes to their composition

have been made in recent years?

The first golf balls were made from wood and this continued until

the early 17th century when the featherie ball added a

new and exciting feature to the game of golf. A featherie is a

hand sewn cow hide leather pouch stuffed with chicken or goose

feathers and coated with paint. Because they were hand produced

and this was a time-consuming process the balls were expensive

and consistency was an issue.

In the 1840's the gutta-percha ball

was invented and it was found that indentations in the leather

helped the ball achieve a truer flight. Ever since then

manufacturers intentionally added indentations to the balls and

now the number of indentations is generally quoted in the

publicity surrounding the ball.

Nike and DuPont teamed up to create a new range of golf balls.

The Nike 20XI ball design replaces rubber cores with a highly

engineered, DuPont thermoplastic (HPF 2000 Mg ionomer) resin

developed specifically for use in golf balls. This advanced core

technology makes the 20XI ball faster, and Nike's new design

makes it possible to achieve both greater distance and greater

control.

Surlyn copolymer

According to the

DuPont web site: DuPont Surlyn ionomer resins are a

family of high-performance ethylene copolymers containing acid

groups partially neutralized using metal salts such as zinc,

sodium and others. The result is an ionically strengthened

thermoplastic with enhanced physical properties versus

conventional plastics. The DuPont manufacturing process for

Surlyn® enables highly tailored combinations of properties:

outstanding resilience, broad hardness and stiffness range, and

excellent resistance to cuts and abrasion - all highly desirable

for golf ball applications.

To meet golf manufacturer needs, DuPont offers more than 20 commercial

grades of Surlyn®, plus a number of grades developed to meet

confidential requests.

See their video describing the

Nike golf ball

A review of the chemistry of golf balls and clubs was recently

published in J Chem Educ

2008, (85) 1319.

Golf

Clubs

The shafts of early Golf club woods were made of different types

of wood before taken over by hickory. The varieties of woods

include ash, greenheart, purpleheart, lancewood, lemonwood,

orangewood, and blue-mahoo. In the middle of the 19th century the

shafts were then being replaced by hickory wood. Despite this

strong wood being the primary material, the long-nose club of the

mid nineteenth century was still prone to breaking at the top of

the backswing. The club heads were often made from thorn, apple,

pear, dogwood, beech in the early times until persimmon became

the main material. Golf clubs have been developed and the shafts

are now made of steel, titanium, carbon fiber, or other types of

metals. The shaft is a tapered steel tube or a series of stepped

steel tubes in telescopic fashion. This has helped the accuracy

of golfers. The grips of the clubs are made from leather or

rubber.

From the early 1930s through the 1970s, the shafts of clubs were

made predominantly from steel. Experiments with lighter aluminium

shafts being deemed unsuccessful due to poor torque performance.

Steel has good shaft performance but is quite heavy for the

average player. Replacing steel with graphite reduced the weight

of the club significantly and allowed for the use of longer

shafts.

Golf clubs can be distinguished by their appearance and use in

the game.

Woods

Most 'woods' are made from different metals, although they are

still called 'woods' to denote the general shape and their

intended use on the golf course. Most woods made today have a

graphite shaft and a titanium, composite, or steel head. Woods

are the longest and the most powerful of all the golf clubs.

Today, many metal wood clubfaces (and most driver clubfaces) are constructed

out of titanium. Titanium has a higher strength to weight ratio than steel

and has better corrosion resistance, so it is an ideal metal for golf club

construction. Manufacturers can also make clubheads with greater volume,

which increases the hitting area, and thinner faces, which reduces the weight.

Irons

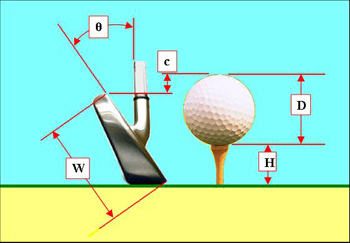

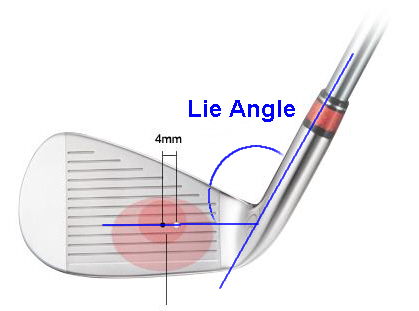

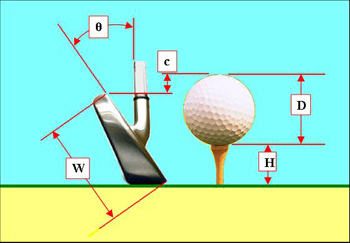

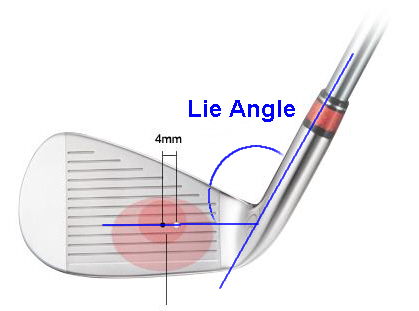

Defining Loft and Lie Angle for Golf Irons

W= clubface width at sweet-spot center, H= tee height, D= golf ball diameter

θ= loft angle

Irons are golf clubs with a flat angled face and a shorter shaft

than a wood, designed for shots approaching the green or from

more difficult lies such as the rough, through or over trees, or

the base of hills. Irons are used during the middle of each hole

off the roughs, fairways or sand traps. There are long irons,

medium irons, and short irons all with flat heads. They are

called irons because they were made of metal.

A recent innovation in the chemistry of alloys has led to what are called

"liquidmetals"

a series of amorphous metal alloys developed by a California Institute of

Technology (Caltech) research team.

Liquidmetal alloys (commercially known as Liquidmetal and Vitreloy) combine

a number of desirable material features, including high tensile strength,

excellent corrosion resistance, very high coefficient of restitution and

excellent anti-wearing characteristics, while being able to be heat-formed

in processes similar to thermoplastics.

One of the first commercial uses of Liquidmetal was in golf clubs,

where the highly elastic metal was used in portions of the face of the club.

These were highly rated by users, but the product was later dropped,

in part because the prototypes shattered after fewer than 40 hits.

Since then, Liquidmetal has appeared in other sports equipment,

including the cores of golf balls, skis, baseball and softball bats,

and tennis racquets.

YouTube clip from Liquidmetal technologies

A recent commercial alloy (Vitreloy 106a) that forms a glass

under less rapid cooling conditions has the composition:

Zr: 58.5 Cu: 15.6 Ni: 12.8 Al: 10.3 Nb: 2.8

Putters

Putters are a special class of clubs with a loft not exceeding

ten degrees (except chippers), designed primarily to roll the

ball along the grass, generally from a point on the putting green

towards the cup. These clubs were originally made of wood but

have now been developed using metals as well. These are the

shortest clubs of the set.

Tennis

Tennis Racquet Strings

A patent for a string

made from gut covered by synthetic fibres was filed in 1982.

How synthetic strings are made

Squash

Why do squash balls

change their properties so much after they have been in use

for a while?

Squash balls are between 39.5 and 40.5 mm in diameter, and have a

mass of 23 to 25 grams. They are made with two pieces of rubber

compound, glued together to form a hollow sphere and buffed to a

matte finish. Different balls are provided for varying

temperature and atmospheric conditions and standards of play:

more experienced players use slow balls that have less bounce

than those used by less experienced players (slower balls tend to

'die' in court corners, rather than 'standing up' to allow easier

shots). Depending on its specific rubber composition, a squash

ball has the property that it bounces more at higher

temperatures. Small coloured dots on the ball indicate its

dynamic level (bounciness), and thus the standard of play for

which it is suited. The recognized speed colours are:

| Colour |

Speed |

Bounce |

| Orange |

Super Slow |

Super low |

| Double yellow |

Slow |

Very low |

| Yellow |

Slow |

Low |

| Green or white |

Medium/slow |

Average |

| Red |

Medium |

High |

| Blue |

Fast |

Very high |

The "double-yellow dot" ball, introduced in 2000, is currently

the competition standard, replacing the earlier "yellow-dot"

ball. There is also an "orange dot" ball, which is even less

bouncy than the "double-yellow dot" ball, intended for use in

areas of high altitude such as Mexico City, Calgary, Denver, and

Johannesburg. The lower atmospheric pressure at these high

altitude regions means that the ball bounces slightly higher,

resulting in the need for such a ball.

The Dunlop squash balls are used in all international

professional competitions. The balls are made of 2 pieces of

extremely durable, high quality rubber compound, glued together

and filled with compressed air. Like compressed air tennis balls,

they lose pressure over time. In addition, as many as 15

different reagents are used, including polymers, fillers,

vulcanising agents, processing aids, and reinforcing materials to

produce the various coloured dot ball types.

Swimming

Competitive

swimwear

Men's swim suits

There was much controversy after the Beijing Olympic Games in

2008, when many Olympic swimmers broke records an unprecedented

number of times using revolutionary swimsuits. It should be noted

that it is rare to break world records, but in 2008, 70 world

records were broken in one year, and 66 Olympic records were

broken in one Olympic Games (there were races in Beijing where

the first 5 finishers were swimming faster than the old world

record). Michael Phelps stated that despite many of his records

having been won in these suits, he might boycott the competition

after his record was beaten by another swimmer with a more

advanced suit.

The Speedo LZR

suit was developed in association with the Australian

Institute of Sport, with the help of Speedo's sponsored athletes.

NASA's wind tunnel testing facilities and Ansys fluid flow

analysis software supported the design. The material used was

woven spandex (elastane) - nylon and polyurethane

Like other suits used for competition, it allows for better

oxygen flow to the muscles, and holds the body in a more

hydrodynamic position, while repelling water and increasing

flexibility. The seams of the suit are ultrasonically welded to

further reduce drag. The suits are manufactured at Petratex, a

textile factory in Paços de Ferreira, Portugal; the

technology is patented in that country. The suit is also 100%

chlorine resistant and quick drying. The suit includes patented

Core Stabilizer and Internal Compression Panels.

The Beijing Olympics proved to be an unprecedented success for

the LZR Racer, with 94% of all swimming races won in the suit.

89% of all medals won at the Beijing Olympics were won by

swimmers wearing the suit. In total 23 out of the 25 world

records broken, were achieved by swimmers competing in the LZR

suit By August 2009, 93 world records were broken by swimmers

wearing a LZR Racer, and 33 of the first 36 Olympic medals have

been won wearing it. Every winner in every men's event in the

Beijing Olympics was wearing this swimsuit.

The number of records broken since the introduction of the

swimsuit prompted the introduction of a new phrase to the sport:

"swimsuit technology doping". In Beijing, Speedo handed out the

suit to any swimmer who wanted to try it and since they were US$

550 each this countered the argument that only rich nations could

afford to use them. However some countries had restrictions due

to sponsorship and initially could not use the suits. The suit

takes around 15 minutes to put on, with the aid of two plastic

bags (one over each foot) and possibly some talcum powder!!

The combined effects of the LZR both compressing the body and

trapping air for buoyancy led to some competitors who used the

LZR to try wearing two or more suits for an increased effect.

Therese Alshammar from Sweden lost her world record in the 50

meter butterfly because she was wearing two swimsuits. However,

all other records set by a swimmer wearing the suit stood as

valid.

The World Swimming Federation's decision to ban hi-tech swimsuits

came amid calls from a number of national swimming federations

who additionally called for all records achieved while wearing

them to be indicated with an asterisk in the record books.

FINA bans hi-tech suits from 2010

Speedo LZR swimsuit now disallowed from competition swim

meets

As of New Year's Day 2010, men are only allowed to wear suits

from the waist to above the knees. They are also only permitted

to wear one piece of swimwear; they cannot wear speedos

underneath jammers. This law was enacted after the controversy in

the Beijing Olympics and Rome World Championships.

Women's swim suits

Women wear one piece suits with different backs for competition,

though there are two-piece suits that can be worn to compete as

well. Backs vary mainly in strap thickness and geometric design.

Most common styles include: racerback, axel back, corset,

diamondback, and butterfly-back. There are also different style

lengths: three quarter length (reaches the knees), regular length

(shoulders to hips), and bikini style (2 piece). Also as of New

Year's 2010, in competition, women are only allowed to wear suits

that do not go past the knees or shoulders.

Equipment - New materials such as carbon fibre

give great strength three times stronger than steel and

flexibility without the weight. Tennis rackets, golf clubs, poles

or vaulting and Formula 1 racing cars all benefit from this -

giving an improved performance.

Pole

Vaulting

Pole vaulting is a track and field event in which a person uses a

long, flexible pole (which today is usually made either of

fiberglass or carbon fiber) as an aid to leap over a bar. Pole

jumping competitions were known to the ancient Greeks, as well as

the Cretans and Celts. It has been a full medal event at the

Olympic Games since 1896 for men and 2000 for women.

One of the most notable examples of innovation in athletics

equipment is the flexible fibreglass pole. In the early 1960s

performances rapidly improved when the relatively rigid poles

made from steel or bamboo were superseded by highly flexible

poles made of fibreglass or carbon fiber which allowed vaulters

to achieve greater height. Physical attributes such as speed and

agility are essential to pole vaulting effectively, but technical

skill is an equally if not more important element. The object of

pole vaulting is to clear a bar or crossbar supported upon two

uprights (standards) without knocking it down.

Competitive pole vaulting began using solid ash poles. As the

heights attained increased, the bamboo poles gave way to tubular

aluminium, which was tapered at each end. Today's pole vaulters

benefit from poles produced by wrapping pre-cut sheets of

fiberglass that contains resin around a metal pole mandrel, to

produce a slightly pre-bent pole that bends more easily under the

compression caused by an athlete's take-off. The shape of the

fiberglass sheets and the amount of fiberglass used is carefully

planned to provide the desired length and stiffness of pole.

Different fiber types, including carbon-fiber, are used to give

poles specific characteristics intended to promote higher jumps.

In recent years, carbon fiber has been added to the commonly used

E-glass and S-glass materials* in order to create a pole with a

lighter carry weight. Pole vaulters do not need a highly flexible

pole to successfully perform a pole vault (a rigid pole will do),

but they can achieve a considerably greater height through

choosing a pole with an appropriate stiffness. Typical pole

lengths are 4.90-5.40 m for elite male vaulters and 4.30-4.60 m

for elite female vaulters.

*S-Glass is 64-66% Silicon dioxide compare to E-Glass at 52-56%.

S-Glass has no Calcium oxide where E-glass has 16-25%. S-Glass

has more Aluminium oxide at 24-26% where E-Glass is 12-16%.

S-Glass has no Boron where E-glass is 5-10%. S-Glass does have

9-11% Magnesium oxide where E-glass very little. The price of

S-Glass is higher than E-Glass. A possible reason for this is

that S-Glass is processed at a higher temperature than E-glass

and burns through oven liners faster and this replacement cost is

the reason for the higher price. S-Glass looks and handles almost

identically but is made from a higher-strength fiber that gives

about 40% higher tensile strength, 20% higher modulus, and

greater abrasion resistance.

As in the high jump, the landing area was originally a heap of

sawdust or sand where athletes landed on their feet. As

technology enabled higher vaults, mats evolved into bags of large

chunks of foam. Today's high tech mats are foam usually 1-1.5

meters thick. Mats are growing larger in area as well, in order

to minimize any risk of injury. Proper landing technique is on

the back or shoulders. Landing on the feet is avoided, to

eliminate the risk of injury to the lower extremities,

particularly ankle sprains.

Rule changes over the years have resulted in larger landing areas

and additional padding of all hard and unyielding surfaces.

The pole vault crossbar has evolved from a triangular aluminium

bar to a round fiberglass bar with rubber ends. This is balanced

on standards and can be knocked off when it is hit by a pole

vaulter or the pole. Rule changes have led to shorter pegs and

crossbar ends that are semi-circular.

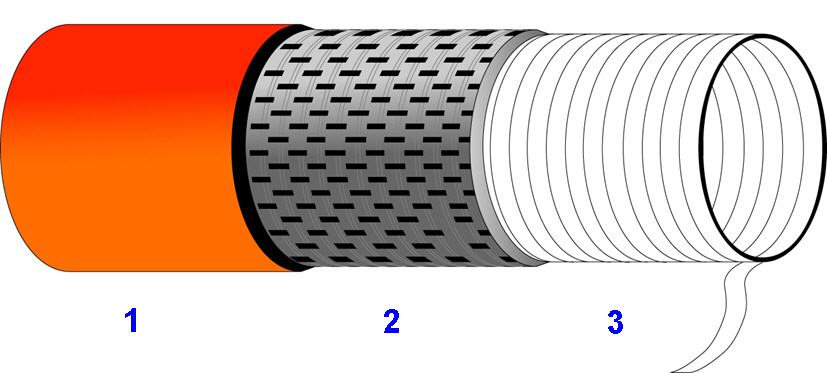

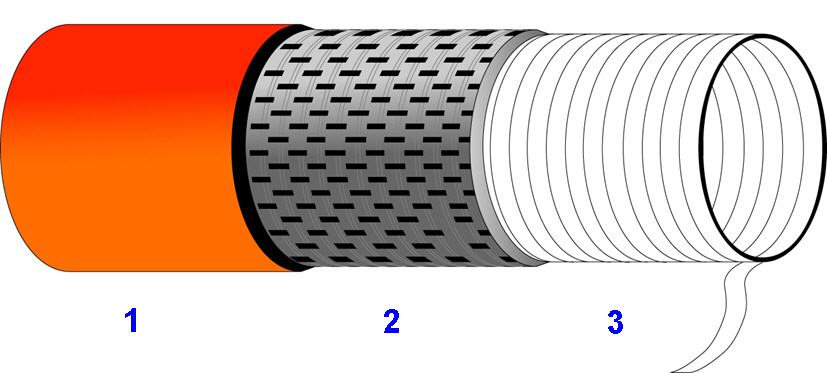

Men's pole vault records and

modern

pole construction

1. Unidirectional carbon fibre / epoxy resin 2. Woven carbon

fibre / epoxy resin 3. Filament wound glass fibre core

Nordic Sport has developed a new pole, which they say is

manufactured from a unique and secret mixture of material.

The mixture is completely different from all other poles on the market.

The Evolution pole has been tested thoroughly with help of both

national and international elite vaulters with very impressive results.

Tests show:

- lighter than a fibreglass pole

- smaller in diameter than a fibreglass pole

- bends easier at the beginning of the vault

- gives a powerful kick-back at the final stage of the vault

Javelin

Throw

The javelin throw is a track and field athletics throwing event

that can trace its origins as a sport back to the Olympic Games

of ancient Greece. In the modem event the javelin must be thrown

using one hand only without the aid of a sling or other throwing

device. Because an athlete can generate a greater release speed

with a lighter implement, the competition rules in the throwing

events always specify a minimum weight for the implement. In the

javelin throw the spear is approximately 2.5 metres in length and

the minimum weight is 800 g for men and 600 g for women. The

javelin thrower gains momentum by running within a predetermined

area.

Rules and Competitions

The size, shape, minimum weight,and center of gravity of the

javelin implement itself are all defined by IAAF rules. In

international competition, men throw a javelin between 2.6 and

2.7 metres in length and (at least) 800 grams in weight, and

women throw a javelin between 2.2 and 2.3 metres in length and

(at least) 600 grams in weight. The javelin is equipped with a

grip, approximately 150 mm wide, made of cord and located at the

javelin's center of gravity (0.9 to 1.06 metres or 0.8 to 0.92

metres from the tip of the javelin for men's and women's

implements, respectively).

The projectile used in javelin consists of three distinct parts:

the head, constructed from a light weight metal; the shaft, made

from carbon fiber or other composite synthetic materials; and the

grip, the portion of the javelin where the object is held by the

thrower prior to delivery. The shaft of the javelin is of hollow

construction to increase the surface area and promote the

greatest flight time. During the first half of the twentieth

century the majority of competitive athletes used javelins made

from Finnish birch wood. Nowadays javelins are constructed from

steel, aluminium alloy, or carbon fibre. A modern javelin differs

from the early designs in that it has a much larger

cross-sectional area. Dick Held is credited with introducing the

'aerodynamic' javelin in the 1950s. His experiments led to the

realisation that it is better for the javelin to have a larger

surface area to augment the javelin's flight capacity through

producing a greater lift.

Javelin Redesign

On April 1, 1986, the governing body (the IAAF Technical

Committee) revised the regulations with respect to the men's

javelin (800 grams (1.76 lb)). They decided to change the rules

for javelin construction because of the increasingly frequent

flat landings and the resulting discussions and protests when

these attempts were declared valid or invalid by competition

judges. In addition, the world record had crept up to a

potentially dangerous level, 104.80 metres by the German Uwe Hohn

in Berlin in 1984 and further increases could result in the

javelin reaching the crowds even in standard athletic stadiums!

The javelin was redesigned so that the centre of gravity was

moved 4 cm forward, further away from the centre of pressure (the

point at which the aerodynamic forces of lift and drag act), so

that the javelin had an increased downward pitching moment. This

would cause the nose to come down earlier, reducing the flight

distance by around 10% and causing the javelin to stick in the

ground more consistently. In 1999, the women's javelin (600 grams

(1.32 lb)) was similarly redesigned.

Modifications that manufacturers made to recover some of the lost

distance, by increasing tail drag (using holes, rough paint or

dimples), were outlawed at the end of 1991. Records made using

such modifications were removed from the record books. The

Finnish javelin thrower Seppo Räty had achieved a world

record of 96.96 metres in 1991 with a modified 'Nemeth' javelin

and this record was nullified. This javelin was designed by

former Olympic Champion, Miklos Nemeth, and had surface roughness

on the tail to reduce aerodynamic drag which was not approved of

by the IAAF. Räty's best record with the current javelin

design was in 1992 (90.60 m), a significant reduction in

distance.

Clothing

Like sports equipment, modern clothing is highly sophisticated

and has a great impact on the feeling of physical comfort in any

kind of sport. Optimal water permeability allows sweat water

droplets out but does not let rain water in. Polyurethane fibres

ensure that the body wear has a perfect fit and offers the

highest comfort because it stretches but still keeps its shape.

Shoes

According to Nick Linthorne at Brunel University:

"For many athletes, running shoes are the most

important piece of their gear. Under IAAF regulations the purpose

of the athlete's shoe is to give protection and stability to the

foot and provide a firm grip on the around. The shoe must not be

constructed so as to give the athlete any additional assistance

and no spring or device of any kind may be incorporated in the

shoe. The design of running shoes has shown a steady evolution

towards minimising the weight of the shoe. A lighter shoe reduces

energy consumption during a distance event, gives a quicker

acceleration and a higher top speed in a sprint and allows a

greater vertical take-off speed to be produced in a high jump or

long jump.

Adidas produces a 'performance plate' that consists of a rigid

carbon fibre plate that is inserted into the sole to stiffen the

shoe. The stiffness of the baseplate of a sprint shoe can have a

significant effect on performance and experiments on sprinters

running over 20 m showed an improvement of just over 1% when

using a stiffening plate in their shoes.

In the high jump, the design of the athlete's

shoe is believed to have a small but significant influence on

performance. In 1957 an athlete using a take off shoe that had a

2-4 cm thick sole set a new world record of 2.16 m. The most

obvious advantage of a built-up shoe is that the athlete's centre

of mass is higher above the ground at take-off and so the height

of the jump is correspondingly increased. Taken to the extreme,

an athlete could wear what is essentially a pair of stilts and

then simply step over the crossbar. The IAAF viewed the built-up

shoe as giving 'unfair assistance' to the athlete and it was

banned shortly after being introduced. However the record was

allowed to stand. Since 1958 the thickness of the sole of the

high jump shoe has been restricted to 13 mm.

Modern Sports shoes are chemical marvels, from the complex

adhesives that ensure the shoe remains intact under extreme

conditions, to the breathing fabrics that keep your feet cool and

dry.

The design

of athletic shoes is one example in which chemistry and

biomechanics are employed to help minimize strain to the lower

body and enhance athletic performance. A shoe should not only

provide support and protection to the foot and ankle, but must

also provide maximum traction and flexibility and, above all, be

lightweight. In track and field sports, for example, a few grams

of extra weight can reduce a runner's speed enough to lose a

race. To this end, manufacturers have introduced ultralight shoes

that use thin, liquid-crystal polymers that act like suspension

bridge cables to resist shoe stretching and maintain stiffness

without adding weight. For cushioning and support, many shoes

employ lightweight gel cavities or air pockets.

Modern athletic shoes have at least four components: the upper,

the insole or insert, the outsole, and the midsole. The upper

holds the shoe together and protects the foot. The insole lies

directly beneath the foot and provides cushioning and arch

support. Insoles are removable in many shoes, and extra insoles

called inserts can be added for comfort or moisture control. The

outsole is the part of the shoe in contact with the ground; it's

usually made of rubber or a synthetic polymer and has treads or

cleats for traction. The midsole is the hidden layer between the

outsole and the insole, mainly designed for shock absorption.

Chemistry of a typical sports shoe

The insole is a thin layer of man-made ethylene vinyl acetate (EVA). The

components of the midsole, which provides the bulk of the cushioning,

will vary among manufacturers. Generally it consists of polyurethane

surrounding another material such as gel or liquid silicone, or polyurethane

foam given a special brand name by the manufacturer. In some cases the

polyurethane may surround capsules of compressed air. Outsoles are usually

made of carbon rubber, which is hard, or blown rubber, a softer type,

although manufacturers use an assortment of materials to produce different

textures on the outsole.

The rest of the covering is usually a synthetic material such as artificial

suede or a nylon weave with plastic slabs or boards supporting the shape.

There may be a leather overlay or nylon overlay with leather attachments.

Cloth is usually limited to the laces fitted through plastic eyelets, and

nails have given way to an adhesive known as cement lasting that bonds the

various components together.

Adidas designed the Lone Star spike running shoe for the 400m

Texan runner

Jeremy Wariner.

The Lone Star featured the first full-length

carbon nanotube reinforced plate and an innovative compression spike.

After studying Wariner's running pattern by high-speed video and pressure

mapping, Adidas' engineers and designers were able to see how Wariner used

each foot as he ran, which in turn enabled them to custom-design a shoe

for his running style. His shoes have differently designed treads for the

right and left foot to assist his cornering.

Stadiums - these days artificial turf, made of

polyolefins to ensure toughness, is used in many stadiums. The

turf is connected to the ground using polyurethane adhesives.

Another type of chemical material, polycarbonates, have become

the preferred material for roofing sporting arenas as they are

lightweight and transparent enabling weird and wonderful

architectural designs. PVC is used in all parts of the stadium

from the flags and banners waved by fans to the seats they sit in

to the field drainage system.

The University of the West Indies (UWI), Mona Campus training facility, used

by Usain Bolt and other Jamaican runners, received a new

Regupol® tartan track in April 2010, with the same Berlin Blue coloured

surface as the Regupol® track at Berlin's Olympic Stadium.

A prefabricated Regupol® elastic layer [4], 10 mm thick, is glued on the

asphalt base [6] (photo at left above). Afterwards the pores of the elastic

layer are sealed with polyurethane [3] and liquid polyurethane [2] is

applied as wear layer to which the

EPDM granules

are added [1].

The top layer [1], usually 3 mm thick, is composed of mixed-size,

spike-resistant EPDM granules embedded into liquid polyurethane.

Copolymerization of ethylene and propylene would result in a saturated

backbone such that sulfur vulcanization could not be used for crosslinking

since no unsaturation exists. To get a sulfur-curable rubber, a non-conjugated

diene is introduced as a third monomer during polymerization. Appropriate

third monomers contain one double bond which takes part in the polymerization

and one which does not. The diene(s) currently used in the manufacture of

EPDM rubbers (ethylene propylene diene Monomer (M-class) rubber) are

DCPD (dicyclopentadiene), ENB (ethylidene norbornene) and

VNB (vinyl norbornene).

International technology gap

A comparison of 2008 Beijing Olympic results for 'Technology

driven sports' such as Track cycling, rowing and sailing with

'Non-technology sports' such as athletics.

| Total medals - 'tech' |

|

Total medals - 'non-tech' |

|

| Great Britain |

24 |

USA |

23 |

| Australia |

7 |

Russia |

18 |

| New Zealand |

6 |

Kenya |

14 |

| Netherlands |

5 |

Jamaica |

11 |

| France |

5 |

Ethiopia |

7 |

| Spain |

5 |

Belarus |

7 |

| Germany |

5 |

Cuba |

5 |

| USA |

5 |

Ukraine |

5 |

| China |

5 |

Australia |

4 |

| Canada |

4 |

Great Britain |

4 |

| Italy |

2 |

|

|

References

"The role

of technology in sporting performance", Prof Claire Davis,

School of Metallurgy and Materials University of Birmingham, UK.

Design and Materials in Athletics. Nick Linthorne shows the changes

technology has made in a number of athletic events and plots the average result

for the 10th best athlete in the world for these events.

Acknowledgements.

Much of the information in these course notes has been sourced

from Wikipedia under the Creative Commons License. Students

taking this course will be expected to contribute to Wikipedia as

a part of their course assignments.

Continue to Medications and Drug

testing or return to

CHEM2402 course outline.

This work is licensed under a Creative Commons

Attribution-ShareAlike 3.0 Unported License.

Return to Chemistry,

UWI-Mona, Home Page

Created and maintained by Prof. Robert J.

Lancashire,

Return to Chemistry,

UWI-Mona, Home Page

Created and maintained by Prof. Robert J.

Lancashire,

The Department of Chemistry, University of the West Indies,

Mona Campus, Kingston 7, Jamaica

Created September 2011. Links checked and/or

last modified 27th November 2014.

URL

http://wwwchem.uwimona.edu.jm/courses/CHEM2402/Sport/Equipment.html

Return to Chemistry,

UWI-Mona, Home Page

Created and maintained by Prof. Robert J.

Lancashire,

Return to Chemistry,

UWI-Mona, Home Page

Created and maintained by Prof. Robert J.

Lancashire,